At Pacific Maritime Group we love our wires. Tow wires. Face wires. Trip wires. Bridles. Whip lines and tugger wires. Wire slings and chokers. Dozens of wires, thousands of feet of wire. When we talk of wire we actually mean wire rope.

Wire rope is a wonder of the modern age. It replaced chain, which is very strong, and fiber rope, which is very flexible, with a product that combines the two. It evolved from wrought iron chains, which were haunted by mechanical failure.

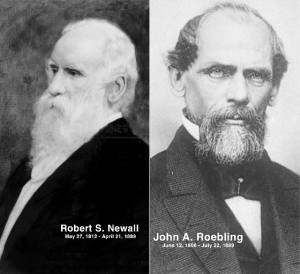

Historians credit German mining engineer Wilhelm Albert with the invention of wire rope in the years between 1831 and 1834. These were three strands of four wires each. Scotsman Robert Newall created four strand wire of four wires each. The inherent springiness of individual wires are set against each other to enable the wire rope to hold its shape.

Wire rope is identified by their components. Albert’s wire rope is known as 3 X 4, and Newall’s as 4 X 4. A common wire now is 7 X 19, which is seven strands each composed of nineteen wires. Modern rope, after decades of technological advances, vary widely in number of strands, left or right twist of wires and in the intended use of the rope.

John Roebling, an engineer living in Pennsylvania, created a 7-strand wire rope that he used for the suspension bridges he was famous for. It is safe to say that without wire rope both elevators and suspension bridges would not exist today. Nothing but wire rope can withstand the swift spooling and continuous strain of an elevator shooting to the top of a skyscraper. The wire rope made for elevators, ski lifts and other critical functions are a specialized wire made to precise specifications. In most of our work at Pacific Maritime Group we use 19 wire or 37 wire strand ropes, which are most commonly used in rigging.

More important to us in the maritime and construction field are what we used a wire for. As a tugboat company we use tow wire daily where one end is the tug drum and the other the tow gear connected to whatever we are towing.

Daily crane work entails a wire that terminates in a hook. The metal weight just above the hook is affectionately known as the “block”.

Slings are used to safely lift items and Pacific Maritime has a wide variety. Note the tags at the swaged ends that attest to it being certified for heavy work. Our DEMAG Crane is rated for 660 tons! The wire rope slings used for such a lift are as thick as your arm.

Other wire rope we use is static in use. It leads to offshore anchors on our Crane Barge PDC-180 or is reeved to lift spuds on our Dredge HORTON.

In short or in long we use a lot of wire rope at Pacific Maritime Group. Next time you pass by one of our work sites pause a moment. Challenge yourself to count the wire ropes in use as we push, pull, lift, dredge or build. They may be items overlooked in a broad view but we value each strand and every wire. They literally are the core of what we do.